What are the reasons and solutions for the hydraulic shearing machine?

Hydraulicplate shearing machineIt is a kind of forging machinery, which is widely used in aviation, light industry, metallurgy, chemical industry, construction, shipbuilding, automobile, electric power, electrical appliances, decoration and other industries. So, do you know the reasons and solutions why the hydraulic shearing machine does not work? Today, Aijiu Library will give you a detailed introduction.

1. Causes of hydraulic shearing machine failure

(1) the overflow valve is blocked.

(2) Electrical limits.

(3) The foot switch and oil pump are damaged.

2. Treatment measures for hydraulic shearing machine without blanking

(1) Remove the oil inlet of the hydraulic swing shear cylinder, and the screw is not completely loosened.

(2) Start the machine and step on the tool. If the oil flows out from the oil inlet, there is no problem with the solenoid valve and overflow valve on the shearing machine, but the pressure does not appear.

(3) the hydraulicplate shearing machineTurn the handle to the desired scale and lock the screw.

(4) When the upper and lower racks move to the bottom dead center, quickly turn the ball valve to close the oil circuit, so that the upper tool holder stops at the bottom dead center, and then continue to slightly open and close the ball valve of the hydraulic plate shearing machine to make the upper tool holder in the whole stroke Rise in segments. At this time, the uniformity of the blade gap can be measured section by section.

(5) When the tool is fed or processed, it needs to run at low speed. At this time, the stepper motor runs at low speed and uses low-voltage power. When the program returns to zero, a fast return is required. At this time, high-speed operation is required and high-voltage drive power is used to increase the output torque and ensure normal return to zero.

(6) There is a switching transistor to control the output of the high-voltage drive power supply. When the switching transistor is damaged and the high speed is reset to zero, the high-voltage power supply cannot be turned on, and the output torque of the stepper motor is not enough, resulting in zero loss and the tool cannot return to the origin. Replace the switching transistor to eliminate this fault.

After the plate shears are installed in the factory, an initial trial shear is required. So, do you know the precautions you need to know during the initial trial cut?

1. Precautions for shear test

(1) When trying to cut plates of different thicknesses, different blade gaps need to be adjusted. If the corresponding blade clearance is not adjusted, the blade durability will be affected.

(2) When shearing, open the pressure gauge switch and observe the pressure value of the oil circuit. When shearing 12mm plate, the pressure should be less than 20MPa. The remote pressure regulating valve is number 9.

(3) When leaving the factory, the pressure is set to 20-22mpa. Users are required to comply with this provision. Without permission, the pressure must not be increased to shear beyond the specified material surface, thereby damaging the machine.

2.plate shearing machineRoutine maintenance

(1) The machine tool is always kept clean, and the unpainted part is free of anti-rust grease.

(2) Regularly replace and fill the lubricating oil in the motor bearing, and regularly check whether the electrical part is running normally, safely and reliably.

(3) Regularly check whether the V-belt, handle, knob and key are damaged. If the wear is serious, it should be replaced in time and reported to the spare parts.

(4) Lubricate and scrub the machine tool 10 minutes before work every day.

(5) Non-designated personnel are strictly prohibited to operate the equipment. People leave the machine and park in normal times.

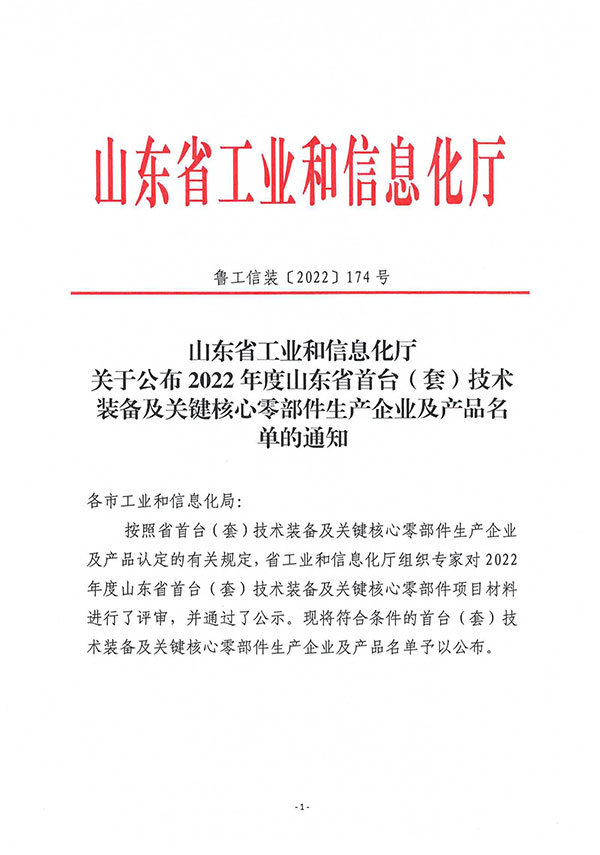

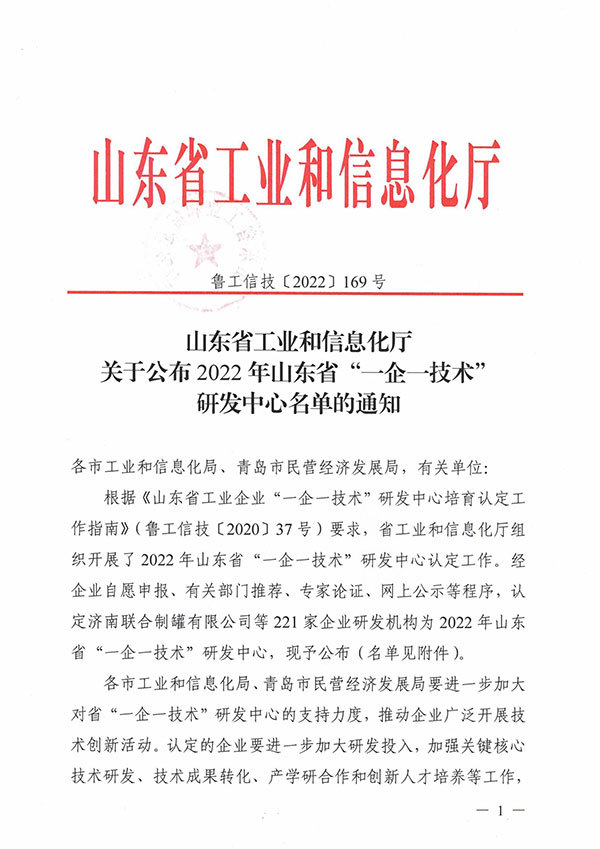

Latest developments