Patent transfer license contact: Mr. Yan

[CN 201710609331.9] Steel for wear-resistant steel for high-speed hammers by double quenching and distribution process and preparation method thereof

[CN 201710609331.9] A Double Quenching and Distribution Process Wear-resistant Steel for High-speed Hammers and Its Preparation Method Title: A Double Quenching and Distribution Process Wear-resistant Steel for High-speed Hammers and Its Preparation Method Application Number: CN 201710609331.9 Applicant: Beijing University of Science and Technology Application Date: 2017-7-25 Patent Type: Invention Application for a Double Quenching and Distribution Process Wear-resistant Steel for High-speed Hammers and Its Preparation Method, Belonging, which Belongs to Metal Material Processing Technology. The wear-resistant steel for high-speed hammers in the double quenching distribution process of the present invention makes the structure of the steel finer and more uniform through a reasonable alloy system composition design and an innovative double quenching distribution process, and the lath width is significantly smaller. The finally obtained dual-phase structure with a controllable proportion has comprehensive mechanical properties of high hardness, high strength, high toughness and high fatigue resistance. Yield strength of material Rp0.2≥ 1550MPa, tensile strength Rm≥ 1950MPa, elongation after fracture A≥ 13%, strong plastic product ≥ 25GPa ·%,V-notch impact energy ≥ 13J, hardness ≥ 55HRC. The membrane-like residual austenite distributed between the martensite lath is not only conducive to coordinating the deformation of the organization under stress conditions, but also has a very obvious effect on hindering the expansion of microscopic cracks, which improves the fatigue resistance of the material and the service life of the hammer. This double quenching distribution process high-speed hammer wear-resistant steel is an ideal material for the steel used in the hammer of the crusher.

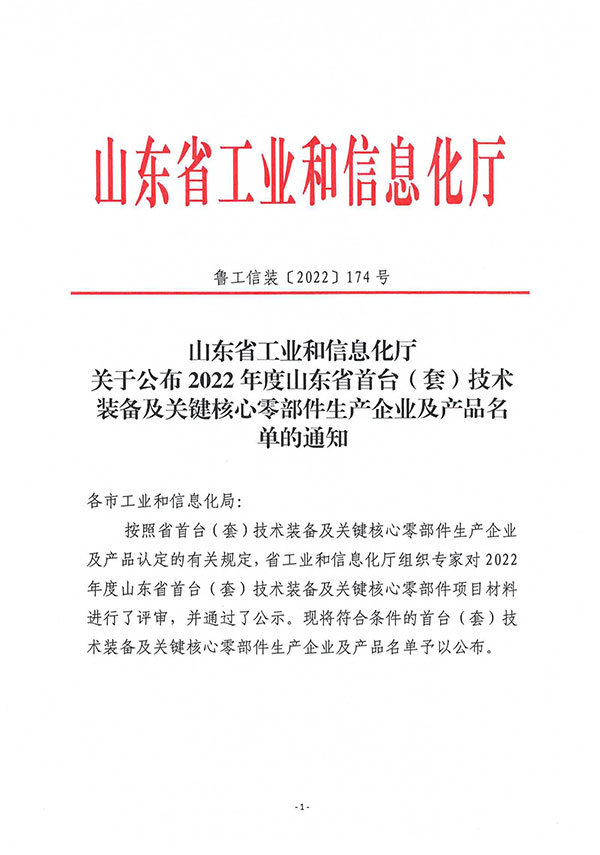

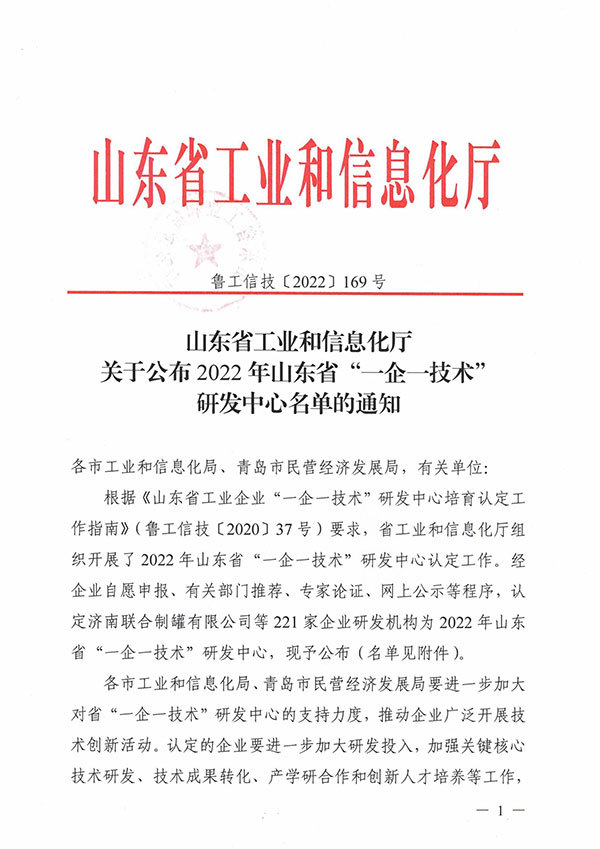

Latest developments

CONTACT US

Telephone:+86 13325294111

Service Phone:+86 400-009-0799

Mailbox:taianhualu@163.com

Address: 2577 Yitianmen Street, Tai'an High tech Zone, Shandong Province

Chinese website:hualu forging press. Website Leveling machine. Website

QR code

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.