Patent transfer license contact: Mr. Yan

[CN 201811519873.8] Method of Forging Hammer Core Forgings of Large Hydraulic Press with 32Mn1 Steel

[CN 201811519873.8] Method Title of Forging Hammer Core Forgings of Large Hydraulic Press with 32Mn1 Steel: Method of Forging Hammer Core Forgings of Large Hydraulic Press with 32Mn1 Steel Application Number: CN 201811519873.8 Applicant: Wuhan Heavy Industry Casting and Forging Co., Ltd. Application Date: 2018-12-12 Patent Type: Invention Application The present invention relates to a method of forging hammer core forgings of large hydraulic press with 32Mn1 steel. Red feed ingot oxygen cut ingot; press Φ800mm-Φ900mm pliers to remove residual materials from riser, wear cap for upsetting, draw and shape, and smooth end face; Normalizing treatment is divided into three stages: 550 ℃ ~ 600 ℃ for 3 hours, 630 ℃ ~ 670 ℃ for 3 hours; 850 ℃ ~ 910 ℃ for 6 hours, then air cooling to 350 ℃ ~ 400 ℃; Tempering, 600 ℃ ~ 670 ℃, heat preservation for 8.5 hours; Then the furnace is cooled and discharged at a temperature lower than 400 ℃. After the flaw detection is qualified, the hardness of the forging body is detected on site to obtain 32Mn1 large hydraulic machine hammer core material. The invention enables the forging to meet the technical requirements of the hammer core forging by adjusting the composition of C and Mn elements and a reasonable heat treatment method. The invention saves the amount of precious alloy and effectively reduces the production cost.

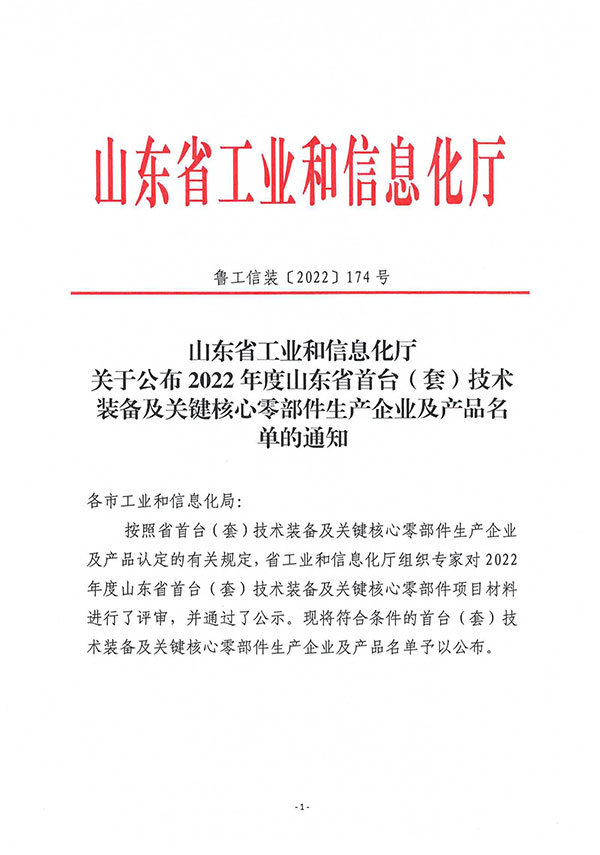

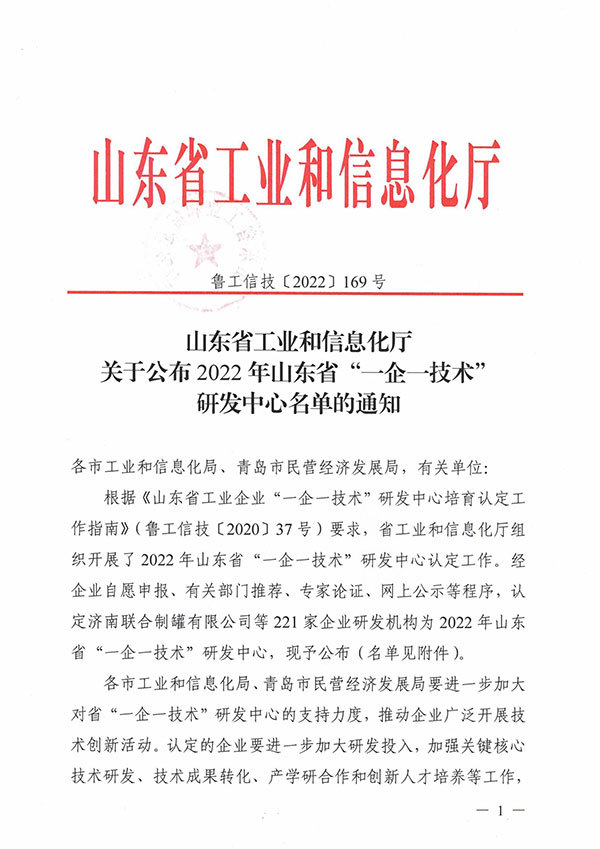

Latest developments

CONTACT US

Telephone:+86 13325294111

Service Phone:+86 400-009-0799

Mailbox:taianhualu@163.com

Address: 2577 Yitianmen Street, Tai'an High tech Zone, Shandong Province

Chinese website:hualu forging press. Website Leveling machine. Website

QR code

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.