The characteristics of common leveling machine

leveling machineIt is a common equipment in plate processing. The setting of the leveling machine mainly depends on the thickness, material and requirements of the strip to be straightened. The thicker the material, the better the structural rigidity, the smaller the number of rolls, the larger the roll diameter, and the greater the power (with a certain width), and vice versa. The specific configuration of the equipment can be determined according to the number and weight of the leveling machine rollers according to customer requirements. Typically, there are two rollers 7, 9, 11 and 13, four rollers 11, 13, 15, 17 and 19 and six rollers 17 and 19.

leveling machineIt has an upper mold and a lower mold. The upper mold is fixedly connected to the push rod of the hydraulic cylinder, and the cylinder body of the hydraulic cylinder is fixed on the support frame; the upper mold and the lower mold are respectively provided with independent cooling water channels, and the outlet and inlet of the cooling water channel are respectively Located on the upper mold or the lower mold. The ratio of the radius/center distance of at least the first five rollers from the entrance of the leveler is the same as that of the traditional leveler, the ratio of the radius/center distance of at least the last five rollers from the entrance of the leveler is similar to that of the curl eliminator, and the increase of the center distance between the intermediate rollers of the leveler is advantageous. It can quickly quench and cool, and at the same time avoid the erosion of impurities on the tool or tool blank, so as to ensure the surface quality and hardness of the tool or tool blank, and avoid the pollution of cooling oil.

The leveling machine is mainly used to correct plates of various specifications and cut them into pieces. The leveling machine is suitable for the leveling of all kinds of cold and hot coil plates. Because the leveling machine is easy to operate, it is widely used in machinery, metallurgy, building materials, electronics, electric power, light industry and other industries, especially shipbuilding, rolling stock, boiler bridge, metal structure factory and other industries, has become an indispensable product in production.

leveling machineIt is mainly used to correct plates of various specifications and cut them into blocks. The machine is suitable for the leveling of all kinds of cold and hot coil plates. Because of its convenient and simple operation, it has been used in machinery, metallurgy, building materials, chemical industry, electronics, electric power, light industry and other industries., Especially shipbuilding, railway vehicles, boilers and bridges, metal structure factories, etc., It has become an indispensable product in production.

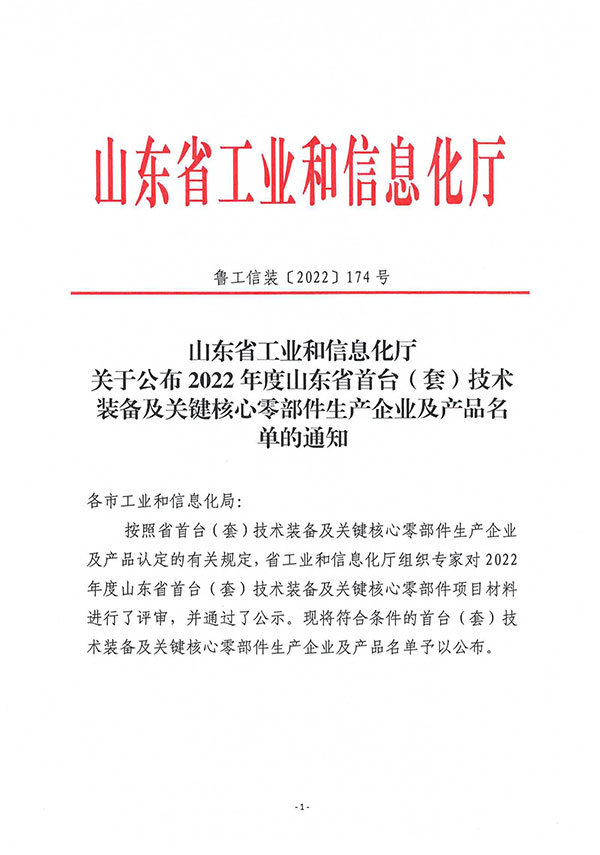

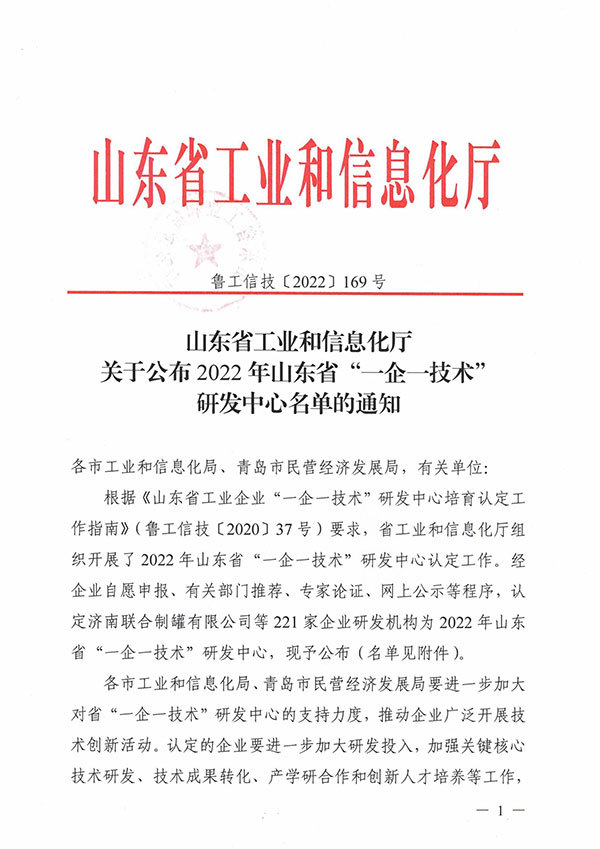

Latest developments