Development Trend of Bending Machine Mould

CNCBending machineThe choice of mold material is the basis for successful cutting. Compared with cemented carbide, the mold speed of PCD CNC bending machine can reach 4000 m/min, while cemented carbide is only 1/4. In terms of service life, the mold of the PCD CNC bending machine can generally be increased by 20 times. From the surface quality point of view, PCD is 30% ~ 40% better than cemented carbide. In addition, the development of CBN (chemical boron nitride) superhard material CNC bending machine molds and surface coating CNC bending machine molds has also contributed to the advancement of cutting technology.

Most users choose CNCBending machineIt is easy to understand that the material grade, processing length and thickness are mainly considered. Of course, this aspect refers to the situation where users handle the goods themselves and can make accurate choices. This is the only way to reduce the cost of output. It is important to know whether the choice of bending machine is appropriate can directly affect the cost.

Generally speaking, it depends on what type of parts the user wants to produce, and makes a choice when determining the conditions of the bending machine, rather than choosing those unwanted tons. In addition, in order to select tonnage specifications, it is possible to choose a greater thickness than that of self-manufactured parts. In this case, it can be guaranteed that the machine will not bear the load under certain conditions, and the guaranteeBending machineThe service life. Of course, if the tonnage is too large, it will affect the accuracy of the manufactured parts, and if it is slightly larger, it will not affect this.

The choice of bending machine is mainly based on the user's own situation, which is certain, and it is also a direct factor to reduce production costs. The bending machine can also be used to crush the edge of the workpiece, first bend the workpiece 30 degrees, and then crush the workpiece with a flat knife. However, the pressing edge of the ordinary punch press should not be arranged on the bending machine as much as possible, because the pressing edge of the punch press is relatively better. When arranging the process, it is often necessary to consider whether the bending is good, because bending is a very important process, and whether the bending is good or not directly affects the guarantee of bending quality. However, improper control of bending size often leads to quality problems, so special attention should be paid to bending in the design process, which is related to the quality stability of products in mass production.

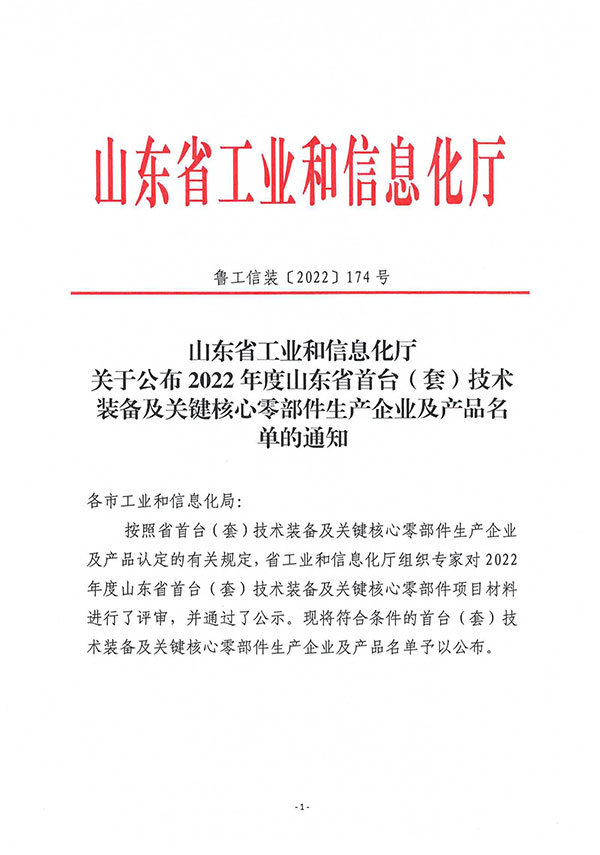

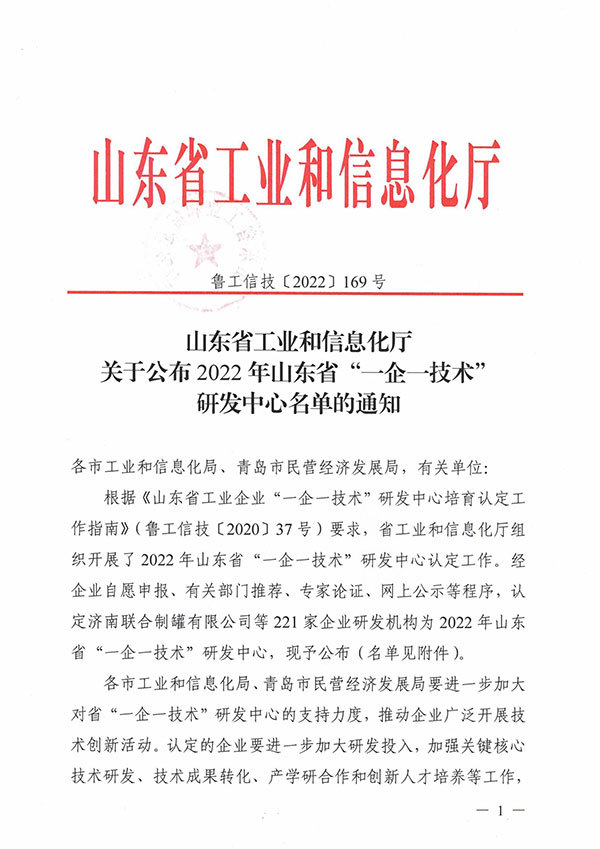

Latest developments

CONTACT US

Telephone:+86 13325294111

Service Phone:+86 400-009-0799

Mailbox:taianhualu@163.com

Address: 2577 Yitianmen Street, Tai'an High tech Zone, Shandong Province

Chinese website:hualu forging press. Website Leveling machine. Website

QR code

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.