What are the structural components of the CNC bending machine and the vulnerable parts?

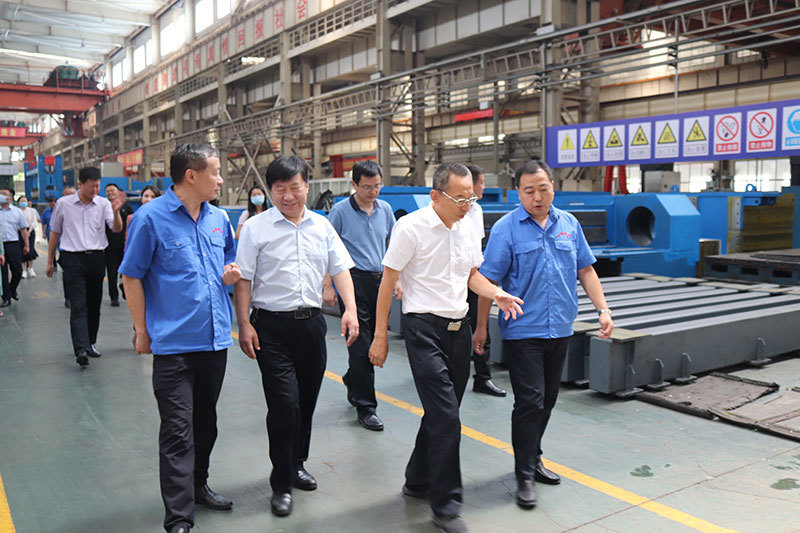

plate bending machineIt is an equipment for bending metal plates with work rolls. It can form parts of different shapes, such as cylindrical parts and conical parts. It is a very important processing equipment. The working principle of the bending machine is to make the work roll move by external force such as hydraulic pressure and mechanical force to bend or roll the plate. According to the rotational movement and position changes of work rolls of different shapes, oval parts, arc parts, cylindrical parts and other parts can be processed, and it is also easy to roll thick steel plates into circles.

three rollersplate bending machineThe six structural components of are:

(1) Upper and lower rollers: important parts of the bending machine, made of forged high-quality carbon steel.

(2) Rack: There is a left rack and a right rack, and the lower roller bearing is installed on the rack. There is a square screw in the frame, and the upper end of the screw is hinged with the bearing seats at both ends of the upper roller.

(3) Reducer: ZSY280 hard tooth surface reducer and pad height are installed on the channel steel base.

(4) Electrical part: all installed in the control box, easy to operate.

(5) Unloading device: installed on the side of the reducer to balance the upper roller during unloading; unloading and recovery are completed by the oil cylinder.

(6) Base: It is welded by section steel and steel plate. Install frame, reducer, motor, etc. form a whole.

The wearing parts of CNC bending machine are generally divided into the following types. Let's take a look.

The sliding bearing between the lower roller, the fixed seat and the turning seat of the bending machine is usually called a composite sleeve. As usual, we accept copper alloy, which has high wear resistance and specific force. However, due to the large amount of fighting, the composite sleeve is easy to wear during use. We encourage customers not to shift gears and refuel, and increase the amount of oil on their fighting surfaces, which can extend the service life of sliding bearings.

2. The reducer can be said to beplate bending machineThe nerve part of the transmission. If used improperly, it will produce abnormal noise, high noise ratio, easy to damage. It is recommended to add 2/3 gear oil per person, and then ensure the stability of rotation and the time of rolling sheet metal. Even if the air intake is small-some or several times, it is likely to make the reducer run more normally and increase the dull service life.

Latest developments

CONTACT US

Telephone:+86 13325294111

Service Phone:+86 400-009-0799

Mailbox:taianhualu@163.com

Address: 2577 Yitianmen Street, Tai'an High tech Zone, Shandong Province

Chinese website:hualu forging press. Website Leveling machine. Website

QR code

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.