Intelligent complete equipment (provide one-stop system solution)

Key words:

Category:

TEL:

Email:

Description

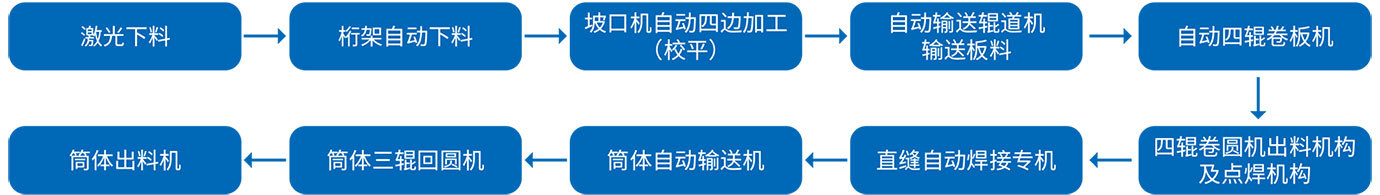

This production line is a turnkey project that is designed, manufactured, transported, installed, debugged and trained according to the user's requirements for the barrel section (except for the basic construction of production line equipment, etc.) until the equipment can be put into normal use to ensure that the whole line can stably produce qualified products and meet the production rhythm requirements.

▶All production line equipment is made of high-quality materials. All mechanical, electronic and electrical components should be made of mature and reliable high-quality products. Key equipment, parts and electrical components adopt international first-class brands.

▶The production line equipment and facility structure design adopt the more advanced technology in the industry, with sufficient strength and rigidity, beautiful appearance, energy saving and environmental protection, good interchangeability, and high degree of automation.

▶The production line equipment and facilities have good operation performance, humanized operation interface and comprehensive protective measures, high reliability, good stability, and convenient use, maintenance and repair.

▶The design and use of production line equipment and facilities conform to ergonomics.

▶Production line system architecture, PLC programming language is unified, and there are corresponding standards or specifications; production line installation and commissioning should have standards or specifications. The main installation methods and installation dimensions of production line equipment (and tooling) shall be in accordance with standards or specifications.

▶Modular and flexible group-to-equipment, group-to-tooling and fixtures are adopted, requiring beautiful appearance, reasonable structure, reliable positioning and convenient operation.

Product recommend

CONTACT US

Telephone:+86 13325294111

Service Phone:+86 400-009-0799

Mailbox:taianhualu@163.com

Address: 2577 Yitianmen Street, Tai'an High tech Zone, Shandong Province

Chinese website:hualu forging press. Website Leveling machine. Website

QR code

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.